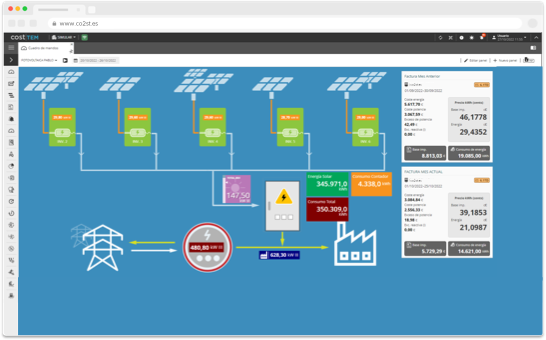

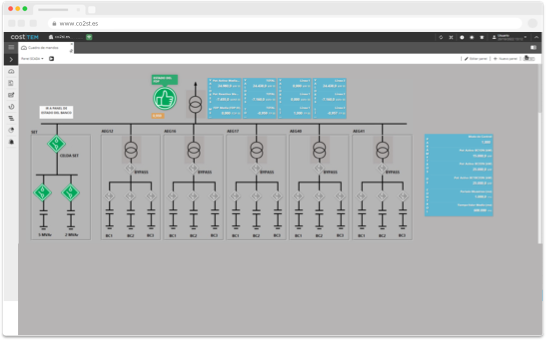

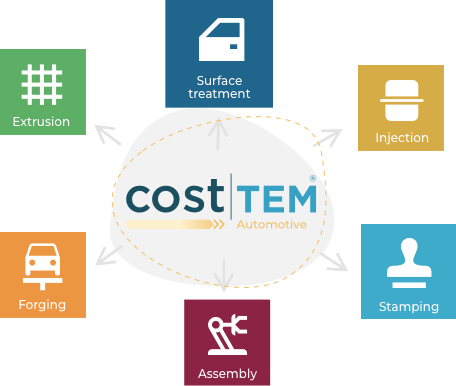

In a sector as competitive and demanding as the automotive auxiliary, it is vital to have a digitalization and monitoring tool, which allows you to carry out the most efficient energy management of your processes.

A tool that, in addition to reducing consumption and energy costs, allows you to incorporate customized production modules that also help you in the technical management of your facilities to find out energy costs per shift, production line, manufactured reference…

The requirements regarding the reduction of GHG emissions make it necessary to have a tool that facilitates their reporting, allowing the automation of the Carbon Footprint calculation.

5% - 15%

Energy savings

< 1.5 years

Investment recovery

2 days

Start-up time

USERS

- Plant Manager

- Maintenance Manager

- Production Manager

- Technical Director

- Purchasing Manager

- Environment Dept.

- COO

- CEO

- CFO / Controller

- CIO